The Zymatic was an ambitious opening preceding an even more ambitious appliance.

Megan Geuss

I’m in my mother’s kitchen in Los Angeles drinking a beer with my

sister on a hot spring afternoon. The beer is a bready, hoppy IPA

without any overwhelming flavors that would make you think too hard. The

alcohol content is acceptable. The brew is properly carbonated and

doesn’t taste flat.

This beer isn’t going to win any awards, but I could

serve it to friends and family without having to apologize for it. In

short, it’s easy drinking, something you can have a conversation over.

The beer, however, came from a beer-making machine on my countertop,

which was why the overwhelming averageness of the brew instead felt

amazing. Maybe that’s a low bar to clear in order to merit applause, but

given my past experience with the PicoBrew Zymatic, it felt

appropriate.

In 2015, I

reviewed the Zymatic,

a large machine that was supposed to help brewers cook up their wort

automatically—but the fermentation process was largely left in the hands

of the Zymatic owner. I produced two below-average beers, perhaps owing

to the heatwave I was brewing in at the time (the temperatures surely

killed off some yeast). But another part of the problem with the Zymatic

was that it combined a machine-driven brewing process with the

traditionally hands-on fermentation, bottling, and carbonating

processes.

It was hardly the “set-it-and-forget-it” appliance that I

expected.

This particular beer I recently drank, however, came from the second

iteration of PicoBrew’s home beer-making appliance: the PicoBrew Pico

(yes, somehow someone decided that was the right name for it). The

second-gen appliance has its problems, but it has also improved from the

previous version in many ways. Most of all, I’m interested in watching

PicoBrew try to solve a problem no one has (that is: “I’m bad at making

beer but buying beer from a liquor store is too mainstream for me”) in a

way that’s actually clever. I probably wouldn’t shell out $800 on this

appliance, but Pico beer making has gotten a bit more compelling.

Keurig for beer? (Wait, hold your groans)

The Pico is about two-thirds the size of the Zymatic, so while it

actually does fit on a countertop this time, it’s still about the size

of a microwave. The Pico probably wouldn’t be a fixture in any but the

largest kitchens.

Operating the Pico requires less work than operating the Zymatic.

That comes with a tradeoff, though: you can only brew with PicoBrew’s

pre-packaged, proprietary PicoPaks. (Yes, “pack” with no “c” because how

else is PicoBrew going to maintain that Silicon Valley glamour?) The

“Paks” come with an RFID tag that the machine reads before you start

brewing.

While this is generally a cringe-worthy way to create repeat customers out of one-time appliance sales à la the Keurig or the

infamous Juicero,

take a deep breath if you find your fingers getting hot and twitchy

with the urge to write a rage comment. For one, the PicoPaks are

compostable, so you’re not doing the same damage done by plastic coffee

cartridges or worthless juice bags. Also, PicoBrew’s website allows you

to buy custom Paks through the "PicoBrew Freestyle” portal (a ripoff of

Coke Freestyle machines, perhaps?). Once you insert a Pak, you can have

the machine make adjustments to brewing temperature and time to reach

desired bitterness levels and alcohol content (ABV, or alcohol by

volume), for example.

The purist will note that you can’t make

any kind of PicoPak

you want in the PicoBrew Freestyle market—they will stop you from

adjusting a recipe’s ratio of certain kinds of grain after a while. This

appliance comes with defined boundaries of all kinds. But it’s also not

going to force you to choke down a narrow variety of hand-curated

concoctions.

PicoBrew is positioning itself to be a sort of rare-beer distributor,

courting breweries of all sizes to “get in the marketplace” by creating

their own PicoPaks that Pico owners can buy. So if you’re a brewer in

Washington state that makes a rare Amber but you can’t afford to ship it

to devotees in Nebraska, you could, theoretically, contract with

PicoBrew to build and sell the, um, “raw” form of your beer.

Setup

When you order a PicoBrew Pico, it comes with a whole slew of parts

besides the machine itself. You’ll get a small brewing keg and a

similarly sized serving keg, as well as a box of components including a

CO

2 regulator and cartridges, an assortment of cleaning

pipes, a small packet of powder detergent for cleaning components after

you brew, and an assortment of plugs and lids for the kegs. For all the

components you’ll encounter, there’s not a lot of mechanical setup

necessary on the machine right off the bat.

Setup was just as easy on the Pico as it was on the Zymatic: connect

to the Internet and your PicoBrew account, wait for any outstanding

firmware to download, and you’re ready to do a first rinse of the

machine. The setup process is made extra-simple here because you don’t

have to go to the PicoBrew Web interface to add the next recipe you want

to brew—the machine will automatically know that information when it

reads the smart label on the PicoPak you insert.

After I unwrapped the Pico carefully and connected it to my home

network, the screen on the appliance walked me through my first rinse.

In general, the Pico’s screen prompts you through the cleaning and

brewing process, but I leaned heavily on the spiral-bound IRL manual

that came in the box because it was more detailed.

Side-quest: Dealing with prototypes

First rinse was easy enough, so I started brewing. I filled the

brewing keg with a gallon and a half of distilled water and added

another gallon to the machine itself (more on why distilled water is

called for below). I unwrapped the PicoPak and the accompanying hop

package that PicoBrew sent me and inserted them into the drawer of the

machine, which PicoBrew calls the Step Filter. The Pico registered that I

wanted to brew a Half Squeezed IPA, and I used the Control Knob to

commence brewing.

The machine started making all the whirring and gargling noises I was

used to on the Zymatic. I went into the next room, reclined on the

couch, and picked up a book.

But about 45 minutes into the two-hour cycle, my ears picked up on an

odd noise. The coffeemaker-esque dripping noises sounded like they were

coming from outside the Pico, not inside.

I ran to the kitchen and, sure enough, grain tea was leaking from the machine all over my kitchen floor.

The leak didn’t seem big at first, so I put a towel under the machine

and a bowl on the floor. I double-checked the ball locks on the keg in

case maybe one wasn’t on correctly and it was backing up water through

the hose or something. I checked to make sure the Step Filter was

properly pushed into the Pico. Everything was locked in place. I let the

brew cycle run all the way through, hoping I could still get wort from

it. But, ultimately, the leak left me too little liquid to work with.

Despite having followed all the instructions, I was convinced some

carelessness on my part caused this.

I rinsed the whole machine out, defeated. Luckily, PicoBrew sent me

two PicoPaks, so I went to the store the next day, bought several more

gallons of distilled water, and ran the thing again, double- and

triple-checking every step.

Again, some kind of leak poured a third of my wort onto my kitchen

floor to my dismay (but to the great amusement of my dog). Evidently,

the angels were getting pretty aggressive in taking their share.

I still assumed I was doing something wrong, but I needed someone to

tell me what it was. I e-mailed PicoBrew, and someone called me back

immediately. Had I checked that the ball locks were on properly? Yes.

Was the Step Filter properly pushed into the Pico? Yes. What did the

holes on the top of the Step Filter lid look like? Well, there’s four in

a row toward the back, one in front of that row on the left, and then

one in front of that towards the center.

There’s your problem, the PicoBrew representative told me. The lid is upside-down. That middle hole should be on the right.

In my defense, there was no way for me to tell that the lid, made of

clear fiberglass, was upside-down. The lid fits into the Step Filter

despite its upside-down or right-side up orientation. PicoBrew explained

that it had sent me a prototype version of the Pico. So rest assured,

dear readers, the version going out to customers now apparently has

clear marking on the lid of the Step Filter to keep this problem from

happening to you.

But this conversation is also how I learned about a key difference

between the Zymatic and the Pico. The Zymatic filled the Step Filter

with heated water via a rotating arm. The water collected in the Step

Filter, mixed with the loose grains, cascaded through the hops

containers before being pumped back out to the keg, where it awaited

yeast and fermentation.

Steam

The Pico, however, uses steam injection to force hot H

2O

into the wort as it passes through the machine. A magnetic valve system

in the upper part of the machine decides where to direct the liquid:

through one of the six holes that drain into the Step Filter, depending

on what point you’re at in the brewing process. The grain bin of the

PicoPak and the accompanying hop containers act like giant tea bags, but

very little of the liquid is meant to collect in the Step Filter

itself. That’s all drained through a hole in the bottom of the Step

Filter and pumped back into the brewing keg for recirculation through

the system.

On the Pico, there’s no moving arm distributing hot water to account

for (meaning the machine can be smaller), but there are small holes in

the machine above the Step Filter that directly correspond to the

placement of each hole in the Step Filter lid. Thus, an upside down lid

created a small flood that resulted in a beery Niagara Falls in my

kitchen.

Despite the lid issue, the steam injection method of heating the wort is an interesting choice. PicoBrew

applied for a patent on the steam injection method in 2015 and was granted it this past January.

One of the advantages of the steam injection method is that it keeps

the lines in the machine relatively clean and kills many bacteria that

might otherwise grow in there, eliminating the need to sanitize the

whole machine. It also allows the appliance to adjust the temperature of

the wort by adding more steam. Directly heating wort to boiling can

create difficult-to-clean sugar residue, but steam injection minimizes

that.

The downside of steam injection is that calculations for how much

water you need to make good wort become more complicated. It’s no longer

“take five gallons of water, add grain, heat.” Instead, it’s “how hot

do you need this recipe to get? How much steam will get it to that

temperature? How much water will that add to the wort? How do you make a

stronger liquid to account for watering it down with steam?”

Luckily, PicoBrew does all that accounting for you. You just need to

buy distilled water to prevent mineral buildup in the lines, the company

says, and follow the directions.

Get wort, ferment!

So, after I ruined two batches of beer with a lid error, I finally

brewed a batch that stayed within the confines of the machine. After

letting the wort cool down overnight, the time had come to add yeast and

ferment.

This is another part of the beer-brewing process that PicoBrew has

tweaked to make a true countertop brewing machine visible on the

horizon. Generally with home brewing, you’re waiting two to three weeks

after you brew for the yeast to ferment your wort before you can bottle

(and then if you use priming sugar to bottle-condition your beer, you

have to wait longer still).

But the Pico’s brewing keg is designed to force a much shorter

fermentation time—for the Half Squeezed IPA, that time could be anywhere

from four to seven days, depending on how warm you keep the wort. The

PicoPaks come with a temperature-sensitive decal that you slap onto the

side of the keg to gauge how warm that wort is.

This fast fermentation is possible because the brewing keg is built

essentially like a pressure cooker. If you keep the yeast warm, they’ll

eat through the sugars in the wort more quickly, releasing carbon

dioxide more quickly as well. This increases the pressure in a container

unless there’s a suitable release valve for that gas. Instead of

letting the beer ferment in a more delicate glass

carboy,

the brewing keg from the PicoBrew Pico has a special seal that

passively pressurizes the wort, allowing faster fermentation without

ruining the beer.

This isn’t a new trick or something PicoBrew invented. Experiments

fermenting under pressure are well documented by home brewers, and a

2001 study even documented how yeast growth and ester production changed with temperature and pressure.

The home brewing forums I visited didn’t report much of a significant

difference between beer brewed in a carboy over a long period of time

and beer brewed under pressure. With the PicoBrew Pico brewing such

small batches, high turnover is a major advantage.

I sat my keg in a warm part of the house and kept an eye on the

temperature decal to make sure it stayed in the right range for five

days.

Now may be the time to mention that, much like the Zymatic, no part

of the Pico instructions encourage you to take gravity readings for ABV.

Perhaps the company assumes that, by following the appliance's

instructions carefully, you’ll come out with a consistent product no

matter what. As with the last review, I neglected to take gravity

readings on my Pico-brewed liquid.

Serving keg

Once the beer fermented, the next step was to put it in a serving keg

and carbonate it. PicoBrew sends you all the tools you need to force

carbonate your beer in the serving keg, so you don’t need to worry about

bottle conditioning unless you want to. Force carbonating in the

serving keg only takes about a day.

This is also the first time in the process that you have to sanitize

anything. Sanitizing is, in my opinion, the worst, most boring part of

brewing, especially if you’re the kind of person that gets a little

neurotic about the idea of beer-ruining bacteria floating around you,

everywhere, threatening to sully your newly sanitized equipment (not

that I know such a person). All of the steps prior to the racking

process benefit from the Pico’s steam-cleaning rinse cycle, so

beer-killing bacteria is of limited concern, according to PicoBrew. I

was happy to only have to make a sanitizing mix once.

After the serving keg and its corresponding lids and tube were

sanitized, I connected one post on the brewing keg back to the Pico and

the other post to a tube I would use to empty the keg. Another great

advantage of the PicoBrew is you don’t need to do any manual syphoning

into your serving vessel—the pump in the appliance moves the beer out

through the serving tube for you. I still had issues with spilling beer

as I shifted the tube from my waste bucket to the serving keg (like with

manual syphoning, you have to dispose of the

trub that gathered on the bottom of the keg). But, all in all, the process was pretty painless.

As luck would have it, I didn’t have a day to force carbonate my beer

after kegging it—I had to drive from Denver to LA, where I’d be staying

for a week. Rather than leave my beer at home—or carbonate the keg and

worry about bumps in the road causing my pressurized alcohol to force

the flimsy plastic lid keeping the keg sealed to pop off—I decided to

bring the uncarbonated beer with me and force carbonate at my mom’s

house.

I made it to LA, and the carbonation process was straightforward. I screwed a CO

2 cartridge into the CO

2 regulator, opened the valve to the right pressure, and let it sit in the fridge overnight.

The next day my sister came by, and we tapped a remarkably decent beer.

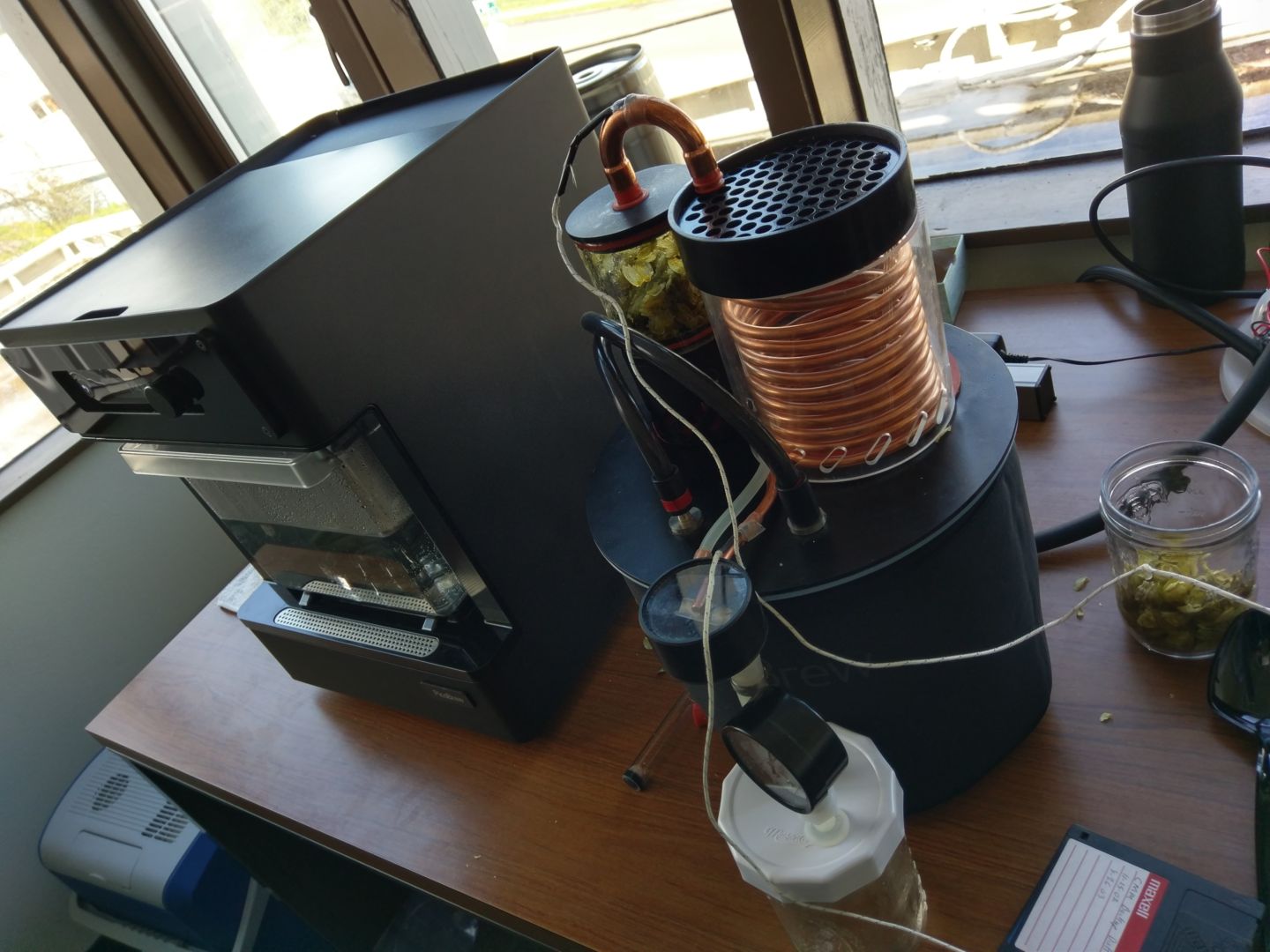

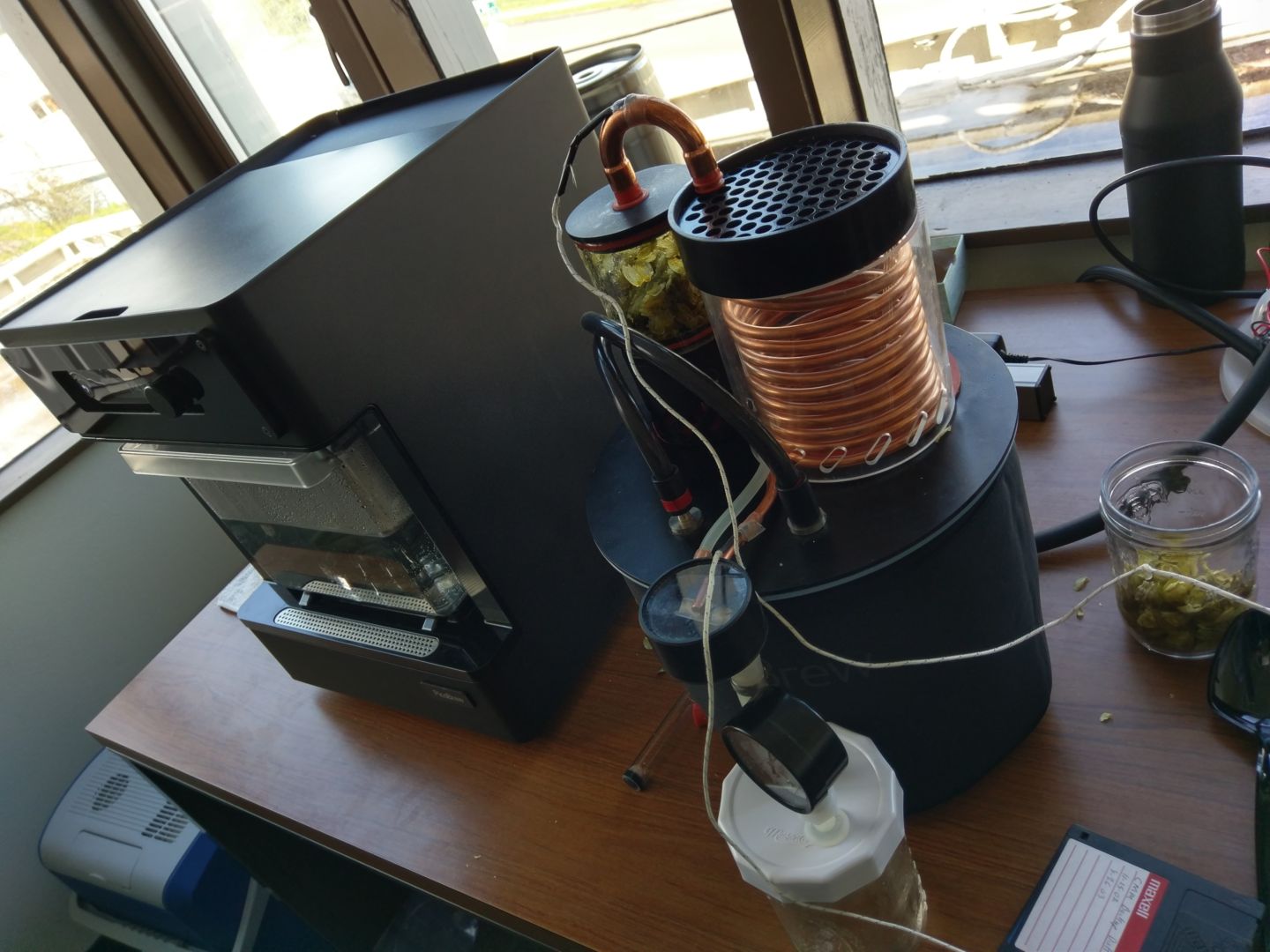

PicoBrew C

That’s not all for the PicoBrew story. Yet again, the company has a

new countertop appliance on the way. This time, the appliance has a far

more sensible name: the PicoBrew C. The company is based in Seattle, so

my Ars colleague Sam Machkovech went to a recent press briefing on the

latest product.

The C will be cheaper than the Pico, at $549, due to how much of the

stainless steel on the Pico model has been replaced with black plastic

on the C. The digital screen is also smaller, and the brewing keg has

been redesigned to eliminate ball locks. As you'll note in the photo

above, PicoBrew is also working on a still to help homebrewers get into

distilling (“We saw a very, very rough prototype that was being used to

distill hop oil,” Sam said). Of course, what you can do with the still

is limited by local laws currently. In my state of Colorado, I’m

permitted to brew beer and wine and grow cannabis and distill my own

essential oils. But I can’t distill even an ounce of my own gin,

according to this

2014 article from the Denver Post.

The Pico C will also lean more heavily on a specially designed app

that will guide a user through the Pak-buying and beer-brewing process.

And if you’re into that kind of thing, PicoBrew’s marketplace will soon

start selling kombucha-brewing kits that you can use in a Pico or a C

model. PicoBrew says the C model and the still will ship in November

2017.

We’re getting closer

Yes, the Pico is hardly perfect, and yes, it still takes a lot of

work and about a week and change before you take that first sweet sip of

beer. But compared to the Zymatic, the Pico is an impressive next step.

We're getting closer to making a coffeemaker for beer. And as I learned

from running two failed brewing sessions due to a misplaced lid, the

work it takes to set up, brew a PicoPak, and clean the components gets

easier and more automatic each time you do it. If nothing else, the Pico

is an interesting chapter in how a startup solved an odd engineering

challenge. Luckily, it actually does brew decent beer, too.

Now, do I think the Pico is a great machine for anyone? Absolutely

not. In most cases, you’ll save time and energy just buying your beer in

a bottle, unless you live somewhere where you can’t get one of your

favorite Northern California brews. While it’s great that the PicoPaks

are compostable, having an additional appliance is a waste in itself

unless you use it regularly. And if the beer-making process is what you

value (because, granted, we all have hobbies that waste money or

resources or time here in America), the Pico takes away from the joys of

putting together a recipe and agonizing over the details.

But the Pico allows a brewer sufficient freedom to make me think this

is not a scam—for the right person. You can create beer recipes in the

PicoBrew Market, you can use the machine as a

sous-vide with

the adapter, you can adjust the settings on the machine to favor or

disfavor certain characteristics of your beer. You can get wonky on it,

if you want.

The good

- This is a solid iteration after the rather unwieldy Zymatic.

- You only have to sanitize the serving keg.

- While you’re constrained from the freedom of traditional home brewing, you can still make adjustments to your beer.

The bad

- The appliance is still large.

- As far as I know, no man is free of the shackles of biology that prevent instant beer fermentation.

- There may not be a huge market for this rather expensive beer-making machine.

The ugly

- You can’t brew anything but proprietary PicoPaks in this machine.

Comments

Post a Comment